MOTOR RACING INNOVATION MEETS PRECISION CRAFTSMANSHIP

Motor racing engine components feature the same highly advanced stainless steel, recognised for exceptional wear resistance and formidable strength enabling speeds of over 200mph (320kmh) and engine rpm of over 15000rpm .

Motor Racing Heritage

Immersed in England's motor racing heritage; our 40-year legacy crafting components for world-championship winning motor racing cars seamlessly transitions to exquisite writing pen collections. Our exclusive writing instruments collections, fuse sophisticated design with manufacturing precision.

Sustainability

Our creations are crafted with eco-conscious elegance, utilising recyclable materials like motor racing high-grade aluminium and stainless steel to offset our carbon footprint. Experience sustainable sophistication.

Expertise

The heart of our writing instrument collection lies many highly skilled machining, hand finishing, and assembly operations taking centre stage in an extensive 8-week production process .

Research and Development

Situated in England, our factory seamlessly blends innovation and meticulous craftsmanship. Through diverse machining, hand-finishing, assembly, and rigorous testing, each writing instrument undergoes an intricate 8-week production. Guided by our commitment to continuous Research & Development as well as sustainability, our collections exude eco-friendly quality and luxury.

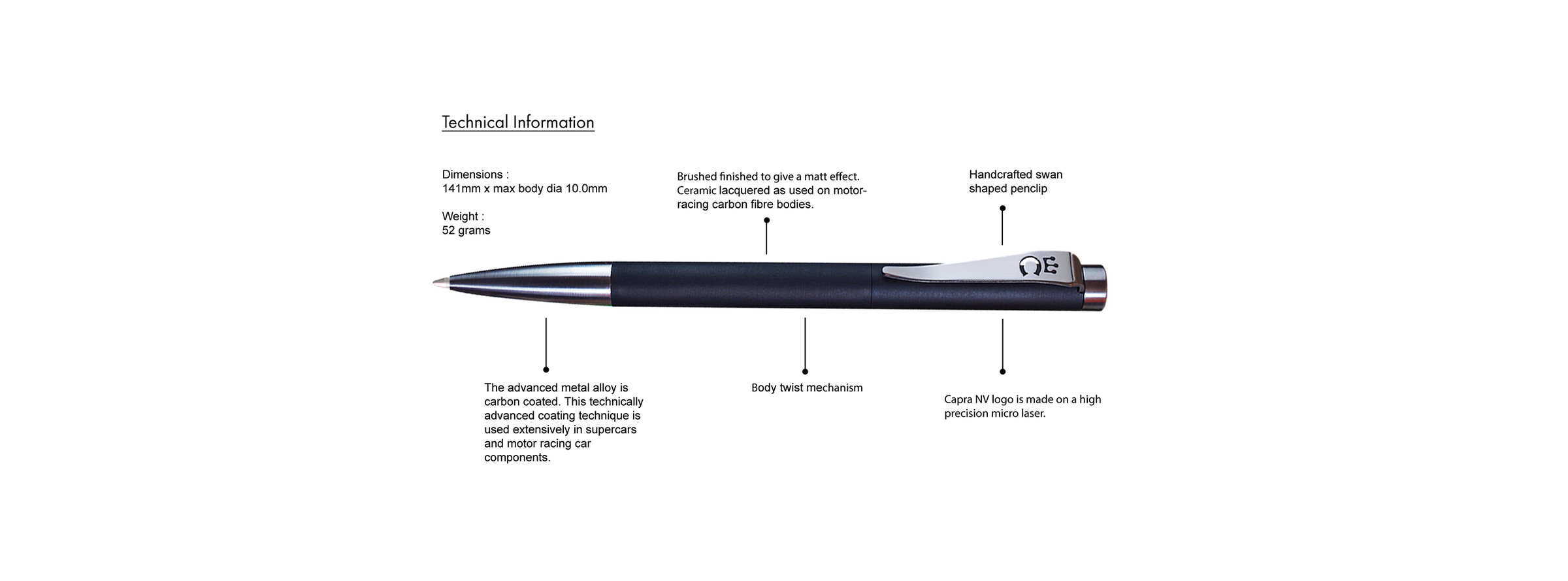

Carbon coating

In the realm of advanced materials; the amorphic carbon coating process is accomplished through a technologically advanced process of heating the components to 900°C and applying titanium carbon coating. The process is also applied on motor racing engine components, for enhanced wear resistance.

Ceramic Coating

The meticulous hand-finishing of ceramic lacquer demands a high level of skill honed over years of expertise. This refined craftsmanship is not only an artistry but also finds application in the coating of motor racing monocoques, showcasing the seamless fusion of luxury and performance.